IBW Additive

HPPS 2 (Batch 5 Payment)

HPPS 2 (Batch 5 Payment)

Couldn't load pickup availability

Welcome to HPPS (High Performance Panel System) Batch 4!

This is HPPS Batch 4; this will likely be the final batch for X1C/P1S HPPS!

If you would like to make customizations to your HPPS unit(s) please add a note to cart!

If you have any questions please email me (peyton@ibwadditive.com)!

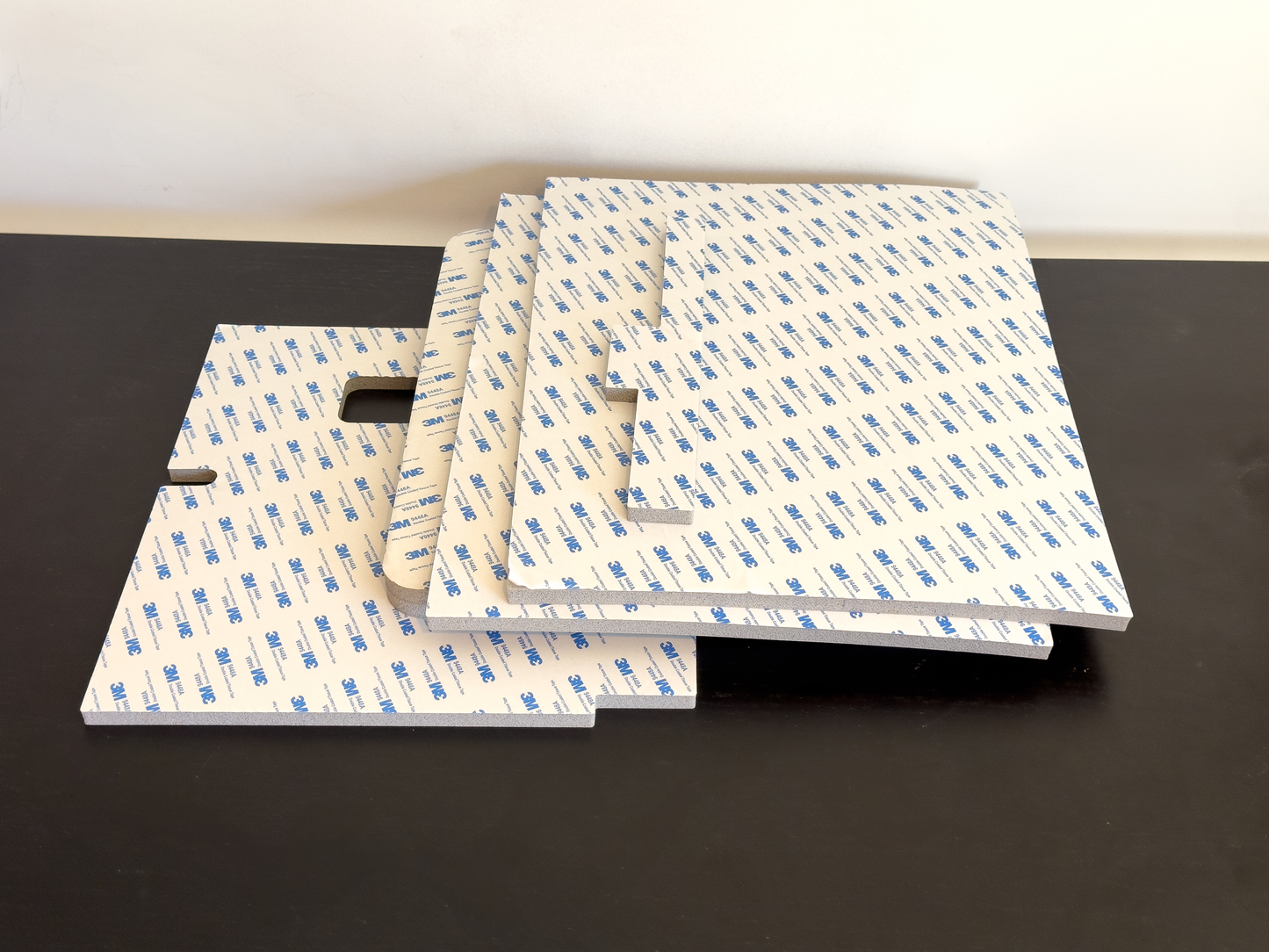

HPPS is the first and only Foamed Silicone panel system for Bambu Labs printers. Designed from the ground, up to be the ideal solution for insulating X1/C/E & P1S in a real-world, safety critical environment.

Unlike any other any other insulation method available, HPPS is not flammable nor emits hazardous, microscopic particles. Furthermore, HPPS is the only plug-and-play insulation system available for X1/C/E & P1S; requiring no measuring, cutting, or added-adhesive.

Made from our proprietary, Gen 4 Foamed Silicone (originally developed by us for a Medical Device application) HPPS is the only foamed silicone on the market at a reasonable cost.

We made a bet that if we invested in the testing, tooling, and made a product that sets itself apart then the users would come; and they did! Batch 1 (100 units) shipped in late March (ahead of schedule) to a very active & enthusiastic customer base. Feel free to ask them anything about HPPS on the Discord!

A DIY solution solution utilizing commercial off-the-shelf foamed silicone panels would require a minimum of 500-700$ in materials per unit (not including labor, research, machining, etc); this has made foamed silicone simply out of reach for anything but the most performant applications such as in aerospace or medicine, until now.

HPPS Performance Data from Real World Testing over the past 6 months:

Decreases total power consumption by 15-30% when

printing higher bed (90C+) temperature materials in a 20C

ambient environment (ABS, ASA, PC, PA6, PA12, PET,

PAHT, PPSU) (20-40% reduction as tested in a 5C env.)

Increases chamber temps without over-temping the

chamber (10-15C increases in a 20C env., 15-25C in a 5C

env.) Panels were developed using thermal timelapses &

analysis to ensure that heat would sink out in 65-70C+

internal chamber temps, protecting the 3D printer.

Allows you to print large out of high-temp materials in

way only possible with an active chamber heater before.

For machines with heated chambers, (X1E or DIY) HPPS dramatically reduces power consumption, increases chamber temperature regularity, reduces thermal losses, and heat-up times.

Allows the printer to print higher-temp materials (ASA/ABS/Nylons/etc.) in a cold (0-5C) shop/garage environment.

Significantly increases the cold to hot-chamber (ready to

print) time of the X1-series (2X the speed to 50C chamber

from 20C ambient

Dramatically increases the fire protection of the 3D

printer; very difficult to ignite, burning does not release

toxic products. Acts to prevent fire spread in tight env.

Power consumption reduction ROI

Please email me @ (peyton@ibwadditive.com) if you would like to purchase 5+ units for your print farm or wish to become a distributor.

Share